Purchasing

While at the store, you fill your cart with a delicious assortment of canned food products, lovingly sealed at peak freshness by infinitely recyclable steel cans.

While at the store, you fill your cart with a delicious assortment of canned food products, lovingly sealed at peak freshness by infinitely recyclable steel cans.

Requiring zero refrigeration energy to store, the food inside your steel cans maintains peak freshness until you are ready to eat it. Which, along with built-in portion control, ultimately reduces food waste.

After preparing an amazing meal for yourself and loved ones that includes some canned goods, you rinse out your steel cans and toss them into your recycling bin.

Steel is collected by your friendly neighborhood recycling people and makes its way to a nearby recycling facility.

As your steel food cans move along the conveyor belt at the Materials Recovery Facility, they are pulled out by a high-powered magnet, then collected to be shipped for processing.

Your steel food cans are melted in a furnace, along with various other scrap steel.

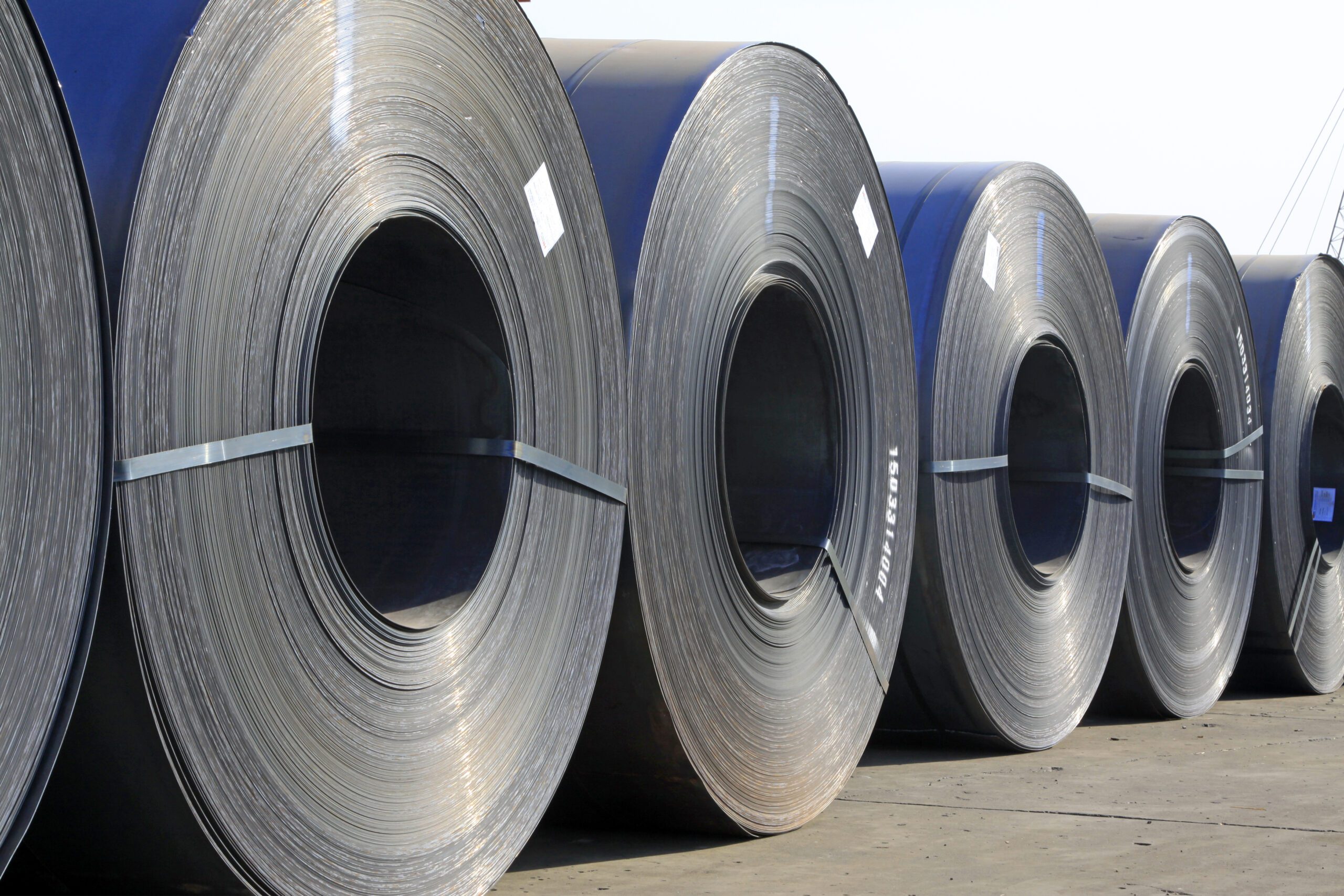

The melted steel is then cast into slabs and rolled into flat stock or steel sheets.

The flat stock is cut into usable sections that are then made into various new steel products, everything from car parts to utensils to new steel food cans (of course!).

100%

The recyclability of steel with no downgrading of material

75%

The percentage of steel ever produced that is still in use today

58%

The recyclability rate of steel cans (the highest of any food packaging)

2.2 billion pounds

The number of pounds of food waste avoided per year globally by choosing metal packaging

35%

The potential amount of recycled steel content in any new steel can

22 million

The tons of CO2 that could be eliminated per year if all fruits and vegetables were canned

#1

Steel cans are the most recycled food packaging in the United States

0

The amount of refrigeration energy used to store steel cans